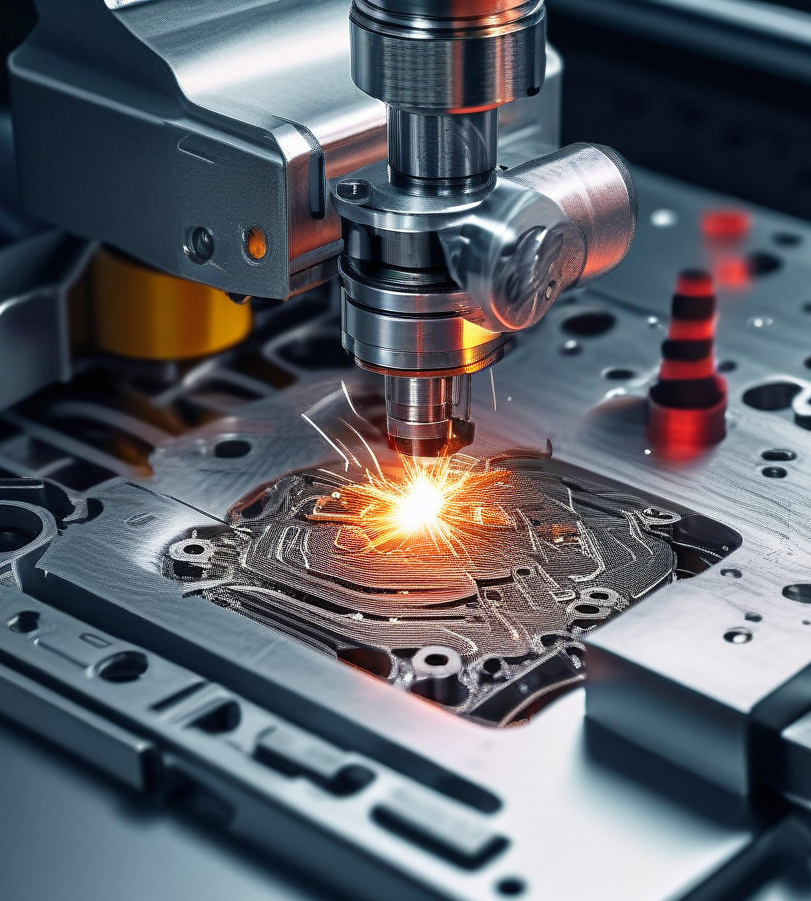

Precision Aluminum CNC Milling

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

Our primary business is CNC processing and we are engaged in the provision of CNC lathe machining service. We have advanced technology and equipment for CNC lathes that will enable us to offer customers high-precision, efficient turning services. What distinguishes our company from others is its focus on excellent workmanship and adherence to quality control standards that guarantee compliance with customer specifications in every product. The major point here is that our experts can design personalized programs for clients as well as delivering all-inclusive technical support and post-sales assistance so as to achieve their satisfaction.

The quality of products and efficiency of their manufacture depend on how well skilled a person is on the area they are working on within the domain of cnc machining. Our company’s team members who undertake cnc lathe operations have great wealth experience in handling different types difficult requirements from clients. Attention to detail is our watchword while striving for perfection all along this line. Continuously optimizing machining procedures as well as raising technical levels serve as benchmarks in setting these activities where it involves turn-milling operations on numerical control machines. We look forward to offer premium standard processing services to our customers just as help them gaining upper hands over market challenges amid fierce trading rivalry.

Quality is at the heart of any service offered under computer numerical control (CNC) machining. Our company has always insisted on the first ideal of quality in its cnc turning services. We strictly control the choice of raw materials and processing processes to ensure that every product meets customer requirements and specifications. Meanwhile, we also have a sound after-sales service system, which is able to provide customers with professional technical support and solutions timely. We always take good care of the people who rely on us to be ahead of our time because we appreciate that without their trust there will not be any prospects for us.

As the manufacturing industry keeps evolving, so does CNC machining with various innovations being made every now and then. As a leading player in cnc machining sector, our company follows closely what is happening in this field including development trends in CNC lathe technology. We are continuously upgrading our capabilities through purchasing sophisticated equipment as well as embracing new technologies. In future development of NC Machining products line, CNC lathe techniques are going to dominate this market segment promoting its growth by injecting fresh energy into it. It is our desire as professionals to satisfy our customers’ needs even more efficiently by offering them high-quality NC Machining services that go hand-in-hand with professional approach we’ve had all these years.

Our company excels in the professional knowhow of CNC lathe processing when it comes to CNC machining. By specializing in CNC lathe machining, we understand how critical this practice is in manufacturing. We are able to offer customers high precision services with high quality through the application of advanced CNC lathes and exceptional operating skills. With an eye for efficient and steady manner, we can meet customer expectations whether they require complex part processes or have needs for mass production.

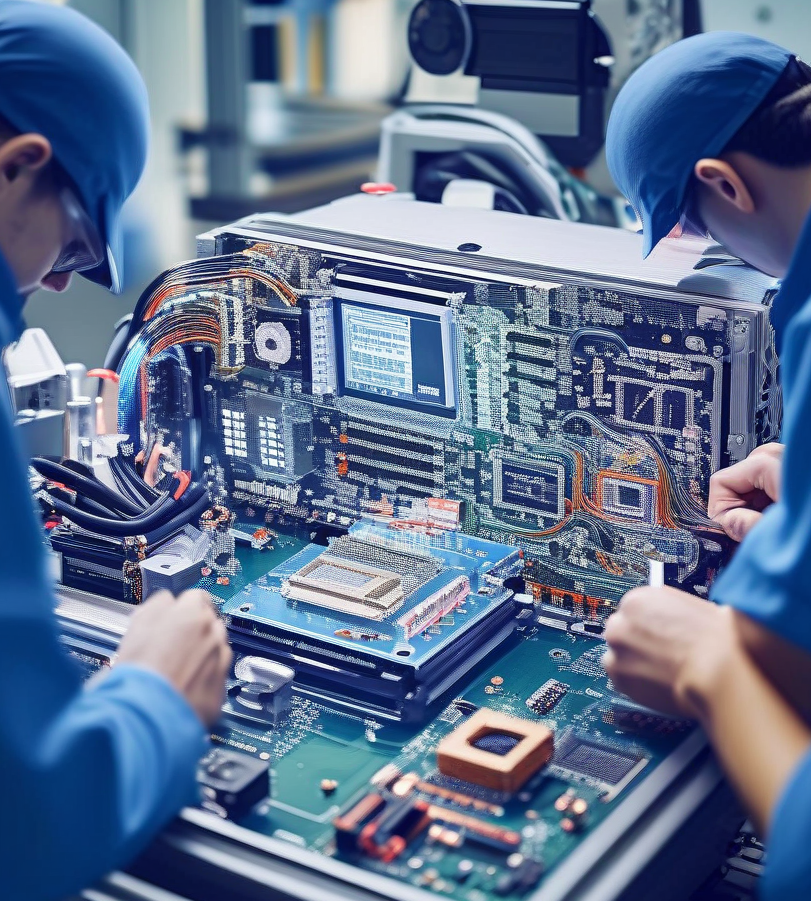

Since its establishment in 2005, Jiayi Technology has been a leading manufacturer and supplier of a variety of ultra-fine quality precision sheet metal parts and CNC machined parts. As a company specializing in CNC machining, we are committed to providing the highest quality precision machining services such as CNC milling, turning, grinding and drilling. With advanced CNC machine equipment and an experienced technical team, we are able to ensure that the processing accuracy and quality of each part reaches the highest standards.

Our services cover a variety of industries, including aviation, automotive, medical, electronics, etc., providing customers with customized solutions to meet their special needs. We understand the importance of time, so we always strive to deliver high-quality products within the stipulated time to help customers maintain their production schedule.

Our goal is to become the world's leading CNC machining service provider through continuous technological innovation and excellent customer service. Whether you are looking for single piece prototyping or mass production, we look forward to working with you to create a better future.

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

Utilizing advanced CNC lathes for turning, enhancing production efficiency and ensuring consistency in part dimensions. Suitable for a variety of materials, including metals and non-metals, guaranteeing durability and stability.

Specializing in high-precision and high-gloss grinding and polishing services to ensure parts meet strict tolerance requirements. Improving part performance and appearance to meet high-end manufacturing standards.

Offering fast and accurate CNC prototyping services, supporting rapid transition from concept design to finished product. Ideal for new product development and small batch production, accelerating market launch.

Our CNC lathes will perform tool calibration and machine tool thermal operation before processing to ensure the stability of the machine tool. At the same time, our engineers will accurately program according to CAD drawings or 3D models, and use high-precision measurement tools to conduct real-time inspection of parts during processing to ensure that the size and shape accuracy meet the requirements.

If you are not satisfied with the finished parts, we provide repair service. You only need to provide detailed feedback and problem description, and we will arrange reprocessing or correction as soon as possible until you meet your requirements.

The minimum diameter that our CNC lathes can process usually depends on the specifications of the lathe and the cutting tools used, while the maximum size is limited by the working range of the lathe. Specific dimensions need to be determined based on your design requirements and our equipment capabilities.

Yes, in addition to CNC lathe processing, we also provide a series of post-processing services, including sandblasting, polishing, anodizing, electroplating, etc., to meet customers' needs for part surface treatment. We can provide surface treatment advice and services based on your specific requirements.

Our CNC lathes can process various metal materials, including but not limited to aluminum alloy, stainless steel, copper, iron, etc. We can also according to customer needs