Precision Aluminum CNC Milling

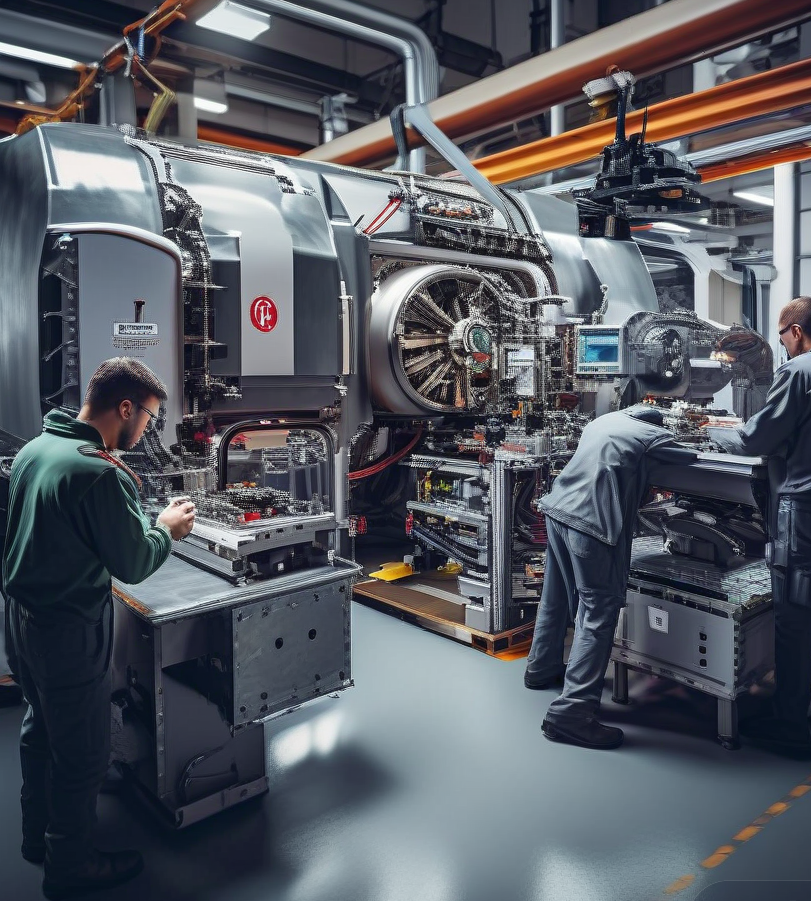

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

We are a professional company in charge of CNC machining providing CNC lathe metal works to customers. We possess advanced CNC equipment, and our technical teams are professionals; we can accurately and quickly finish all the work related to metals. The traits make us distinguished because they include accuracy, speed, and assurance of quality of products; however, our competitive edge is derived from the wealth of expertise in this industry and full service provision that allows us to provide clients with comprehensive solutions.

Quality is a must-have factor in any CNC machining industry, especially in metalworking area. Quality always comes first when it comes to our firm’s cnc machine tool metallurgical services. Therefore we pay strict attention to material selection, equipment adjustment and processes so that each step becomes accurate. The accuracy and surface quality of metallic pieces can be guaranteed up-to-the-mark by the correct operation of cnc tools hence leading to excellent processing quality.

In The competitive market environment, our firm has become one of the most trusted providers of professional cnc machine tool metal processing services. Customers have to trust us because we know that it is not easy to gain such a thing, so we always serve everyone as per their needs. In our company, customer satisfaction is the main priority; thus, there is a provision of customized processing solutions and service packages which are remarkable. Our services range from technical consultation, development of processing plans to after-sales assistance where we shall be fully committed towards helping you out in all cases. Selecting us implies selecting professionalism, confidence and victory too.

With great development rates being experienced in manufacturing industry so are expanding applications of cnc machine tool metal working activities. Our company being a professional cnc service provider has gone beyond the traditional mechanical processing sector into investigating how such fields as new energy cars etc.can benefit from using cnc machine tool metallurgy Low carbon energies such as wind energy have been achieved through close cooperation with clients thereby giving rise to numerous patents.

Innovation is an essential element required for promoting growth within the CNC machining industry. In this respect, our company has remained innovative when it comes to CNC machinery metal works over time. Processing efficiencies have been improved through adoption of new technologies, equipment varieties and methodologies. We also pay close attention to working with scientific research institutions and universities so that we can introduce high quality technical personnel and initiate strong support for the innovative development of the company. We believe that technological innovation will lead to a brighter future for metal machining by CNC machine tools.

Since its establishment in 2005, Jiayi Technology has been a leading manufacturer and supplier of a variety of ultra-fine quality precision sheet metal parts and CNC machined parts. As a company specializing in CNC machining, we are committed to providing the highest quality precision machining services such as CNC milling, turning, grinding and drilling. With advanced CNC machine equipment and an experienced technical team, we are able to ensure that the processing accuracy and quality of each part reaches the highest standards.

Our services cover a variety of industries, including aviation, automotive, medical, electronics, etc., providing customers with customized solutions to meet their special needs. We understand the importance of time, so we always strive to deliver high-quality products within the stipulated time to help customers maintain their production schedule.

Our goal is to become the world's leading CNC machining service provider through continuous technological innovation and excellent customer service. Whether you are looking for single piece prototyping or mass production, we look forward to working with you to create a better future.

Employing cutting-edge CNC technology to ensure precision and surface finish of aluminum parts. Suitable for complex shapes and fine details, offering custom services to meet specific requirements.

Utilizing advanced CNC lathes for turning, enhancing production efficiency and ensuring consistency in part dimensions. Suitable for a variety of materials, including metals and non-metals, guaranteeing durability and stability.

Specializing in high-precision and high-gloss grinding and polishing services to ensure parts meet strict tolerance requirements. Improving part performance and appearance to meet high-end manufacturing standards.

Offering fast and accurate CNC prototyping services, supporting rapid transition from concept design to finished product. Ideal for new product development and small batch production, accelerating market launch.

Our CNC machining has a high degree of accuracy and consistency, allowing products to meet strict quality standards; we can improve your production efficiency, ensure high material utilization for processing tasks, and reduce waste; as well as better cost control

Our CNC machined metal processing services are widely used in many fields, including automobile manufacturing, aerospace, medical devices, electronics industry, machinery and equipment manufacturing, and any industry that requires precision metal parts.

Our CNC machining can handle a variety of metal materials, including but not limited to various carbon steels, alloy steels, stainless steels, aluminum alloys, copper, brass, etc. We select appropriate materials and processing strategies based on our customers' specific needs.

Yes, our CNC machining is fully capable of handling complex metal part designs. As long as you provide detailed engineering drawings and specification requirements, our team of experts will ensure that the parts are manufactured precisely to your design requirements. We also provide technical support to help optimize designs for production.

We ensure the quality of our products through advanced CNC equipment, strict quality control processes and experienced technical personnel. Every production step is inspected in detail to ensure high standards of tolerance and quality requirements are met. In addition, we provide comprehensive post-processing services such as deburring, polishing and surface treatment to ensure the appearance and functionality of the finished product.