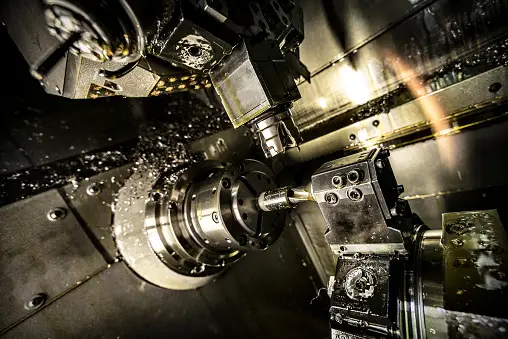

Precision Metal Machining A Gateway to Innovative Production

Among high-quality production, precision metal machining holds a central position in the manufacturing industry. The procedure involves cutting tools and various equipment which are used to remove material from a workpiece with very high accuracy levels in order to achieve exact dimensions as well as surface finish.

Significance of Precision Metal Machining

Industries such as aerospace, medical automotive electronics etc., rely on this kind of technology for creating complex parts or components. High tolerance requirements and strict adherence to specifications are demanded by these sectors due to their critical application areas. Any slight mistake can cause failure or even dangerous situations hence making it necessary for safety purposes during production processes.

Precision Metal Machining Methods & Techniques

CNC (Computer Numerical Control) Machining – This is where cuts with high repeatability are carried out using computer controlled machines.

Milling – Refers to a process whereby material is removed from the workpiece through trimming action done by milling cutter against its surface.

Turning – Material gets eliminated from rotating workpiece while being cut off by means of turning tools held against it; this produces smooth finishes on cylindrical surfaces like those found in shafts or rods.

Grinding – It involves use an abrasive wheel for removing small amounts of materials achieving very shiny surfaces at the end.

Polishing & Lapping – These two methods are employed when highest quality surface finishes required on metal parts they do not alter shape nor size significantly during processing unlike other operations such as grinding would do.

Applications in Different Sectors

Aerospace industry uses precision metal machining mainly for creating engine components that require super tight tolerances together with high strength properties. In automotive manufacturing intricate pieces like gears and engine blocks can only be made possible through employing this technology. Medical devices heavily depend on it in terms of functional requirements as well safety concerns while electronic gadgets demand miniature sizes yet accurate features for example smart phones or computers need small sized components with high density interconnections among them.

Over time, there have been advancements made within precision metal machining owing to new materials being discovered and introduction cutting edge technologies into practice areas. For instance, there has been an emergence of titanium alloys which are stronger than any other material currently known thus enabling reduction weight without compromising strength. Laser cutting along electrical discharge machining (EDM) among others also contribute towards better accuracy during operations.

Recommended Products

Hot News

-

Advantages of CNC machining

2024-01-16

-

What is CNC machining technology?

2024-01-16

-

The development trend of CNC machining

2024-01-16

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS