| Service |

Customized OEM / ODM |

| Quotation |

According to your drawing (size, material, thickness, processing content and required technology, etc) |

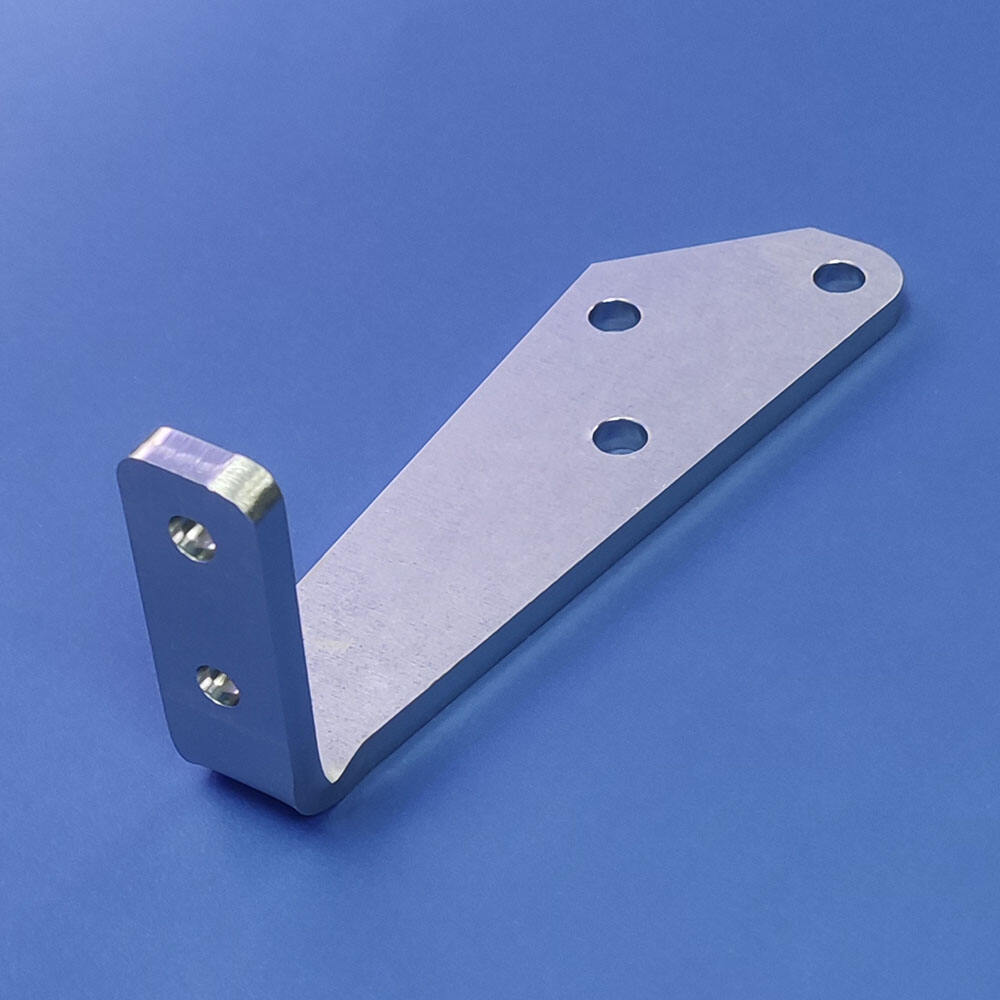

| Materials Available |

Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Surface Treatment |

Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

| Processing |

Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding etc |

| Drawing Formats |

PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

| Our Advantages |

1.) 24-hour online service & Quick Quote/Delivery. |

|

2.) 100% QC quality inspection before delivery, and can provide quality inspection form. |

|

3.) 18+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

|

Tolerance丨Surface Roughness

|

CNC machining: 0.01 minimum, sheet metal fabrication: 0.1 maximum, FTICF: 0.1mm maximum

|

| MOQ |

1 |

| Sample Service |

Available before bulk order. Sample charge per your design, The sample fee can be deducted from the payment for mass production. |

| Sample lead time |

7-10 days |

| Mass Production Lead Time |

10-30 days per your order quantity |

| Packing |

Customers' requirements |

| Place of Origin |

China |

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS